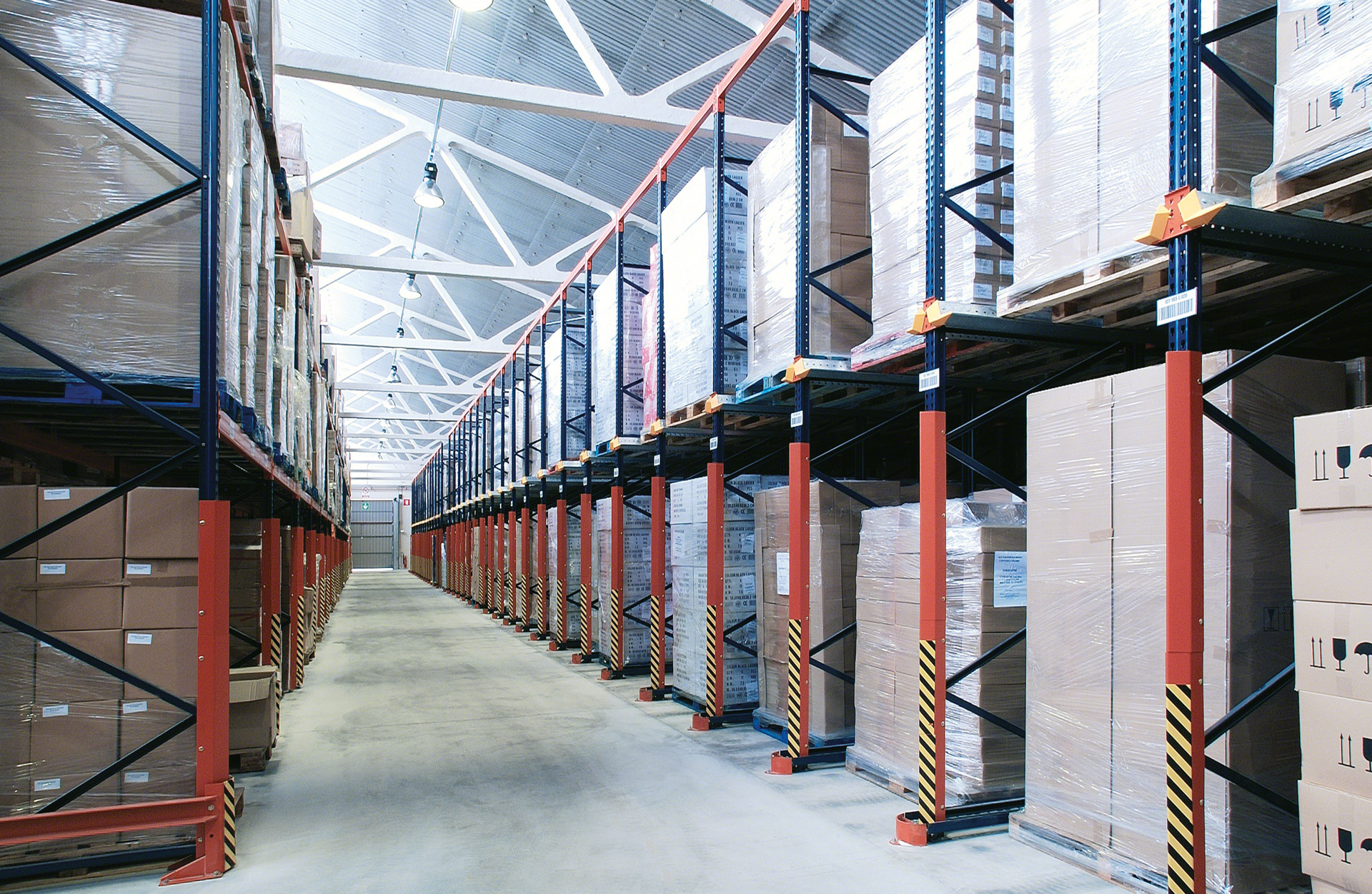

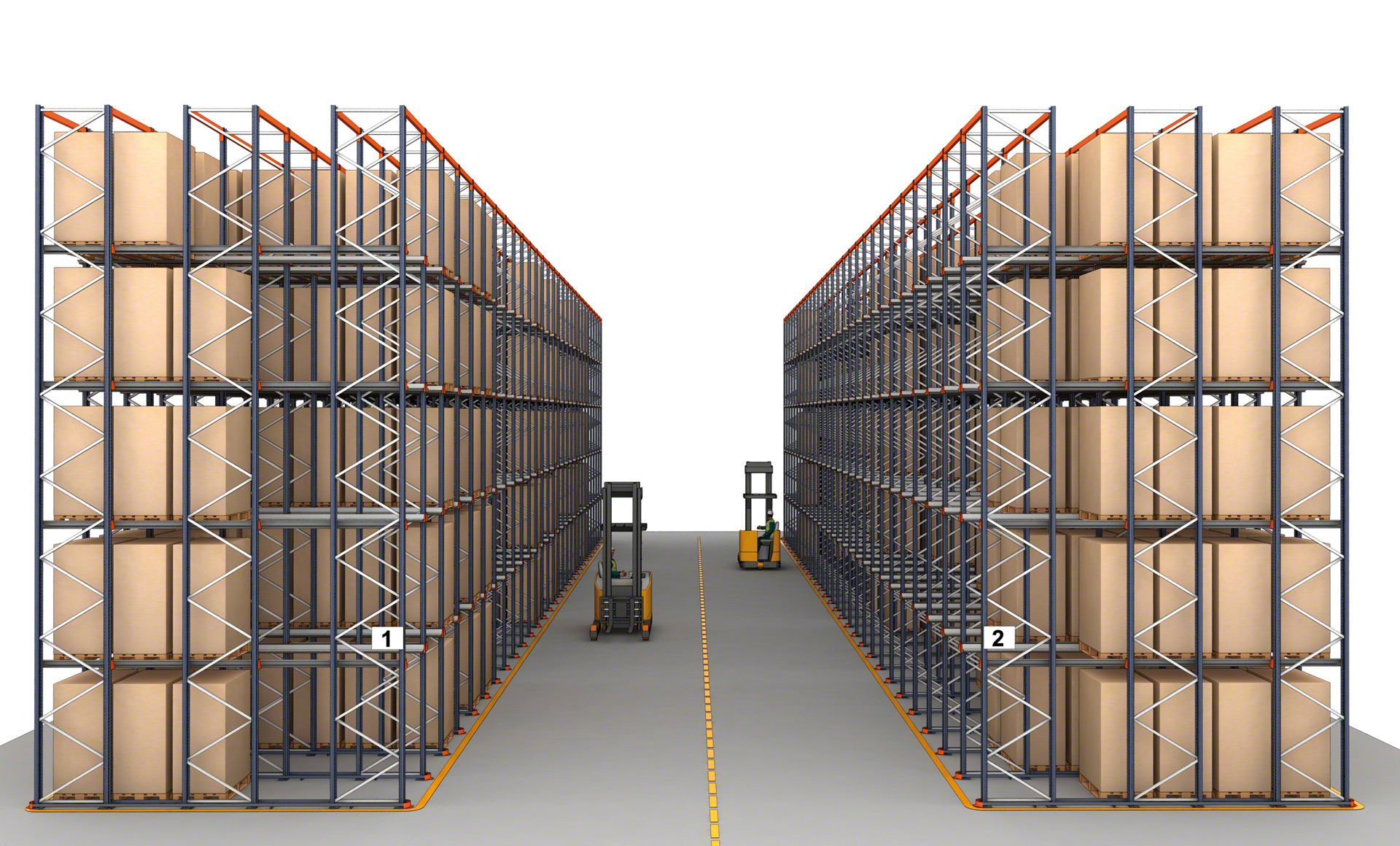

Drive-in pallet racking

Optimizing available space. Elimination of aisles between shelves. Admits as many references as load lanes.

Appropriate system to store homogeneous, low-rotation products with a large number of pallets per reference.

cdfe80c1-cf95-02bb-c1c1-a6acf360a1cd

e604030f-c897-96df-bcfe-c996239a8e61

2601a17f-4b0b-13f9-8320-29f63678eba9

2d3b8d07-fba0-e999-97da-0ae6e8ce4155

c556bfa2-2a30-a562-6b2b-cc131a39f7d5

768c52c6-4755-27d8-9ede-7ec28ecd3d9d

6e57a2c9-e5b3-a6f7-2bc7-2291308c2404

e3db9b5c-af08-b44a-59a8-d93d0d090f37

86119baf-9f19-2692-22ea-6fdf3cdf3252

79130508-f834-c7c5-a204-74de89038759

6e487454-5da3-84b8-05a9-cb191da4cf21

261f4da2-0b2c-d4d7-67bc-9da66104e54a

fbcc40f1-d70c-53bb-a7f5-8f74138608fd

2d7ad099-a963-f605-fb21-a5d58938bb91

9f737e6c-d6f1-9434-26aa-17332391f712

a5c62ab2-e7fd-5ab2-2a56-8cee202411b9

f299c07f-034d-5987-50b8-254a2dc235a2

c97efd1a-a546-2b87-7dc8-67ef47582969

3476fd83-2e0c-8d58-2683-e79b64efaabc

93576626-fdbb-1eed-9e94-75adcb82b299

f61167e4-05b4-9d78-6e5e-10ae29f96949

3cba1bbe-0f7b-6c34-ef50-b3af7837da9e

77f1aa92-14f8-1903-8171-505162f365c4

a93ccb50-08f2-86d8-9259-362d34c4787e

0f0aae1c-d190-143c-6e7d-6894c8485726

60379f39-21a7-cb95-a4c9-bba6b9ef7ab6

e541ce18-acc9-ea71-6c0f-da1ecaf670e7

2c59d719-0e4b-757c-052c-2d11ea9d7e68

a56ec26a-22eb-4168-2dd1-2222e9087ef2

bf8013e3-218b-1dc2-91f1-37cd4f462b52

922e55af-88e8-bf41-0172-f0176901a545

6cbbae1c-bf4c-f0aa-c8e2-7ddc97283c50

786a0891-44f1-3ff3-32b9-aafddc79cbd8

04db3701-2a8c-5a98-9a86-e091f00e9f42

73a9a9ed-9ba2-567d-1932-8c36a8eeb63a

5940cc4c-3573-0a5f-dc56-0226f6bd0743

e79c1ee3-0331-8aea-d540-ac71376eca87

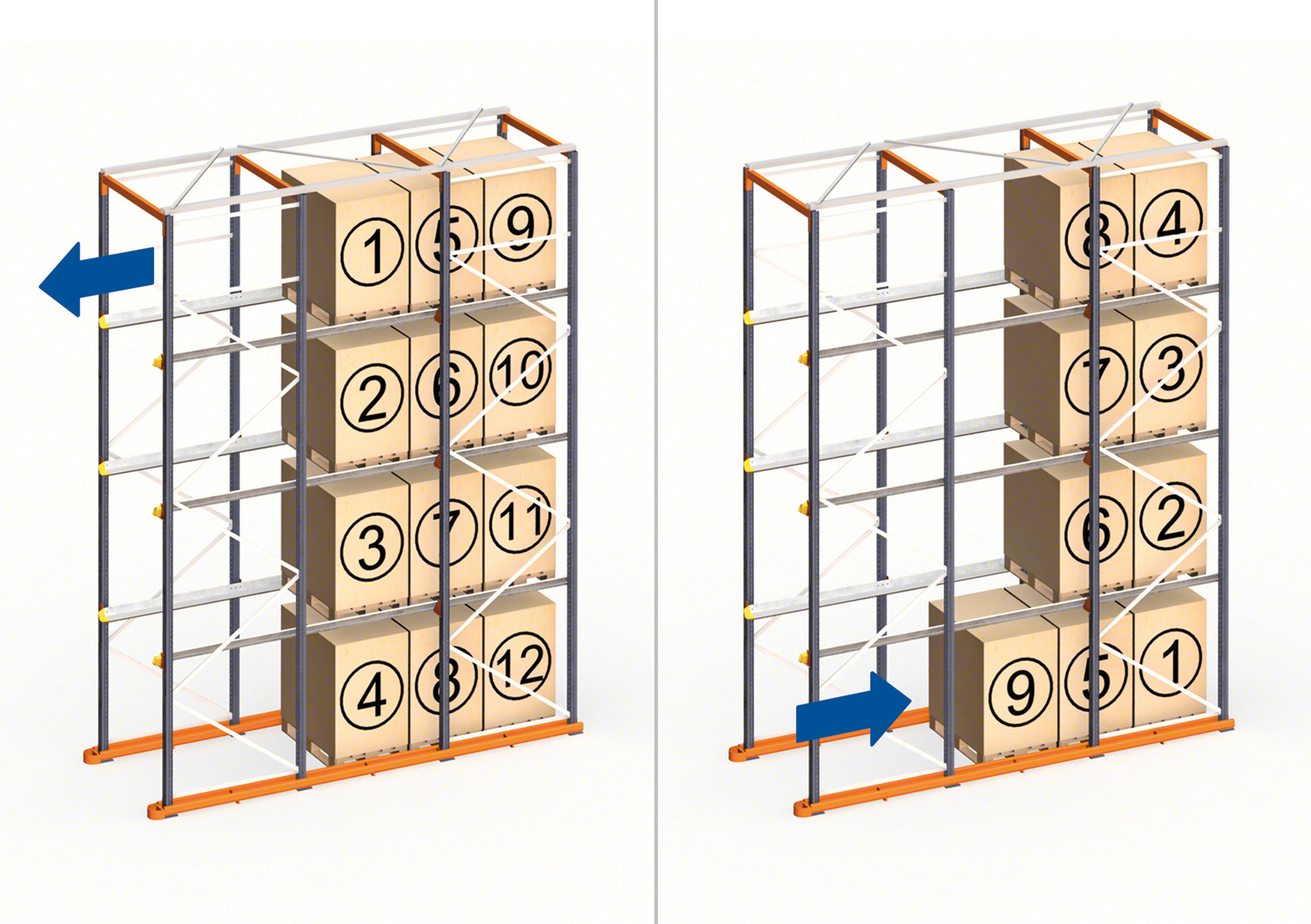

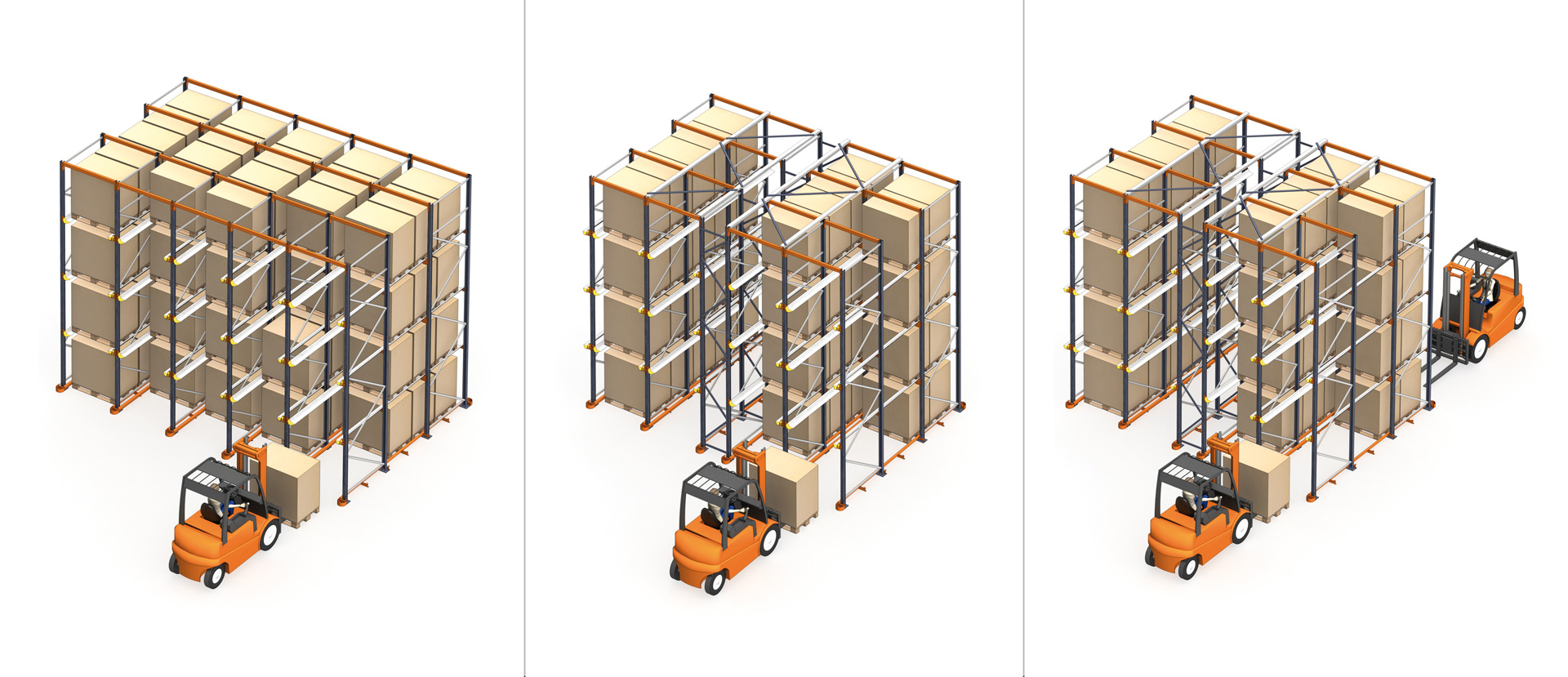

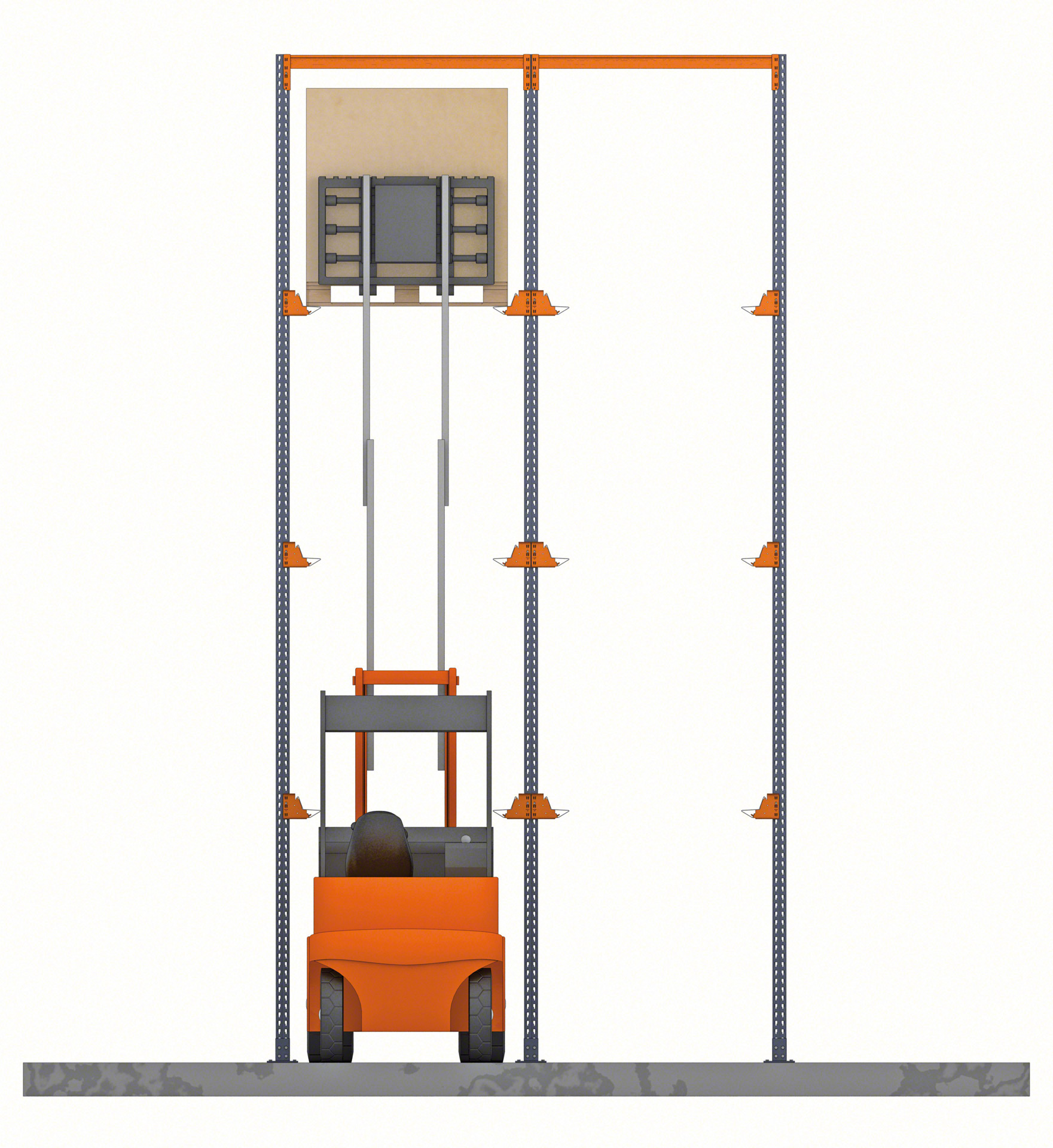

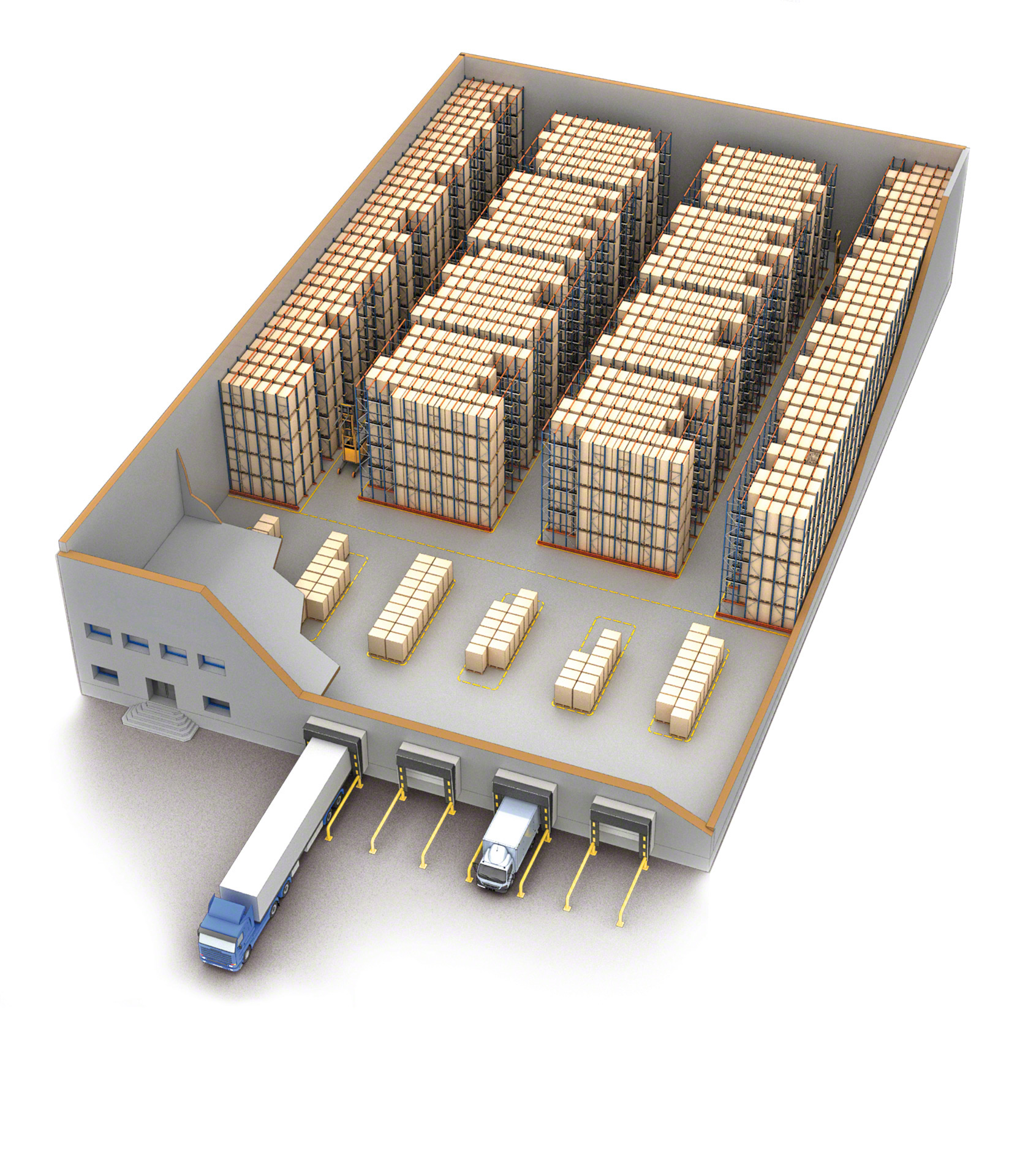

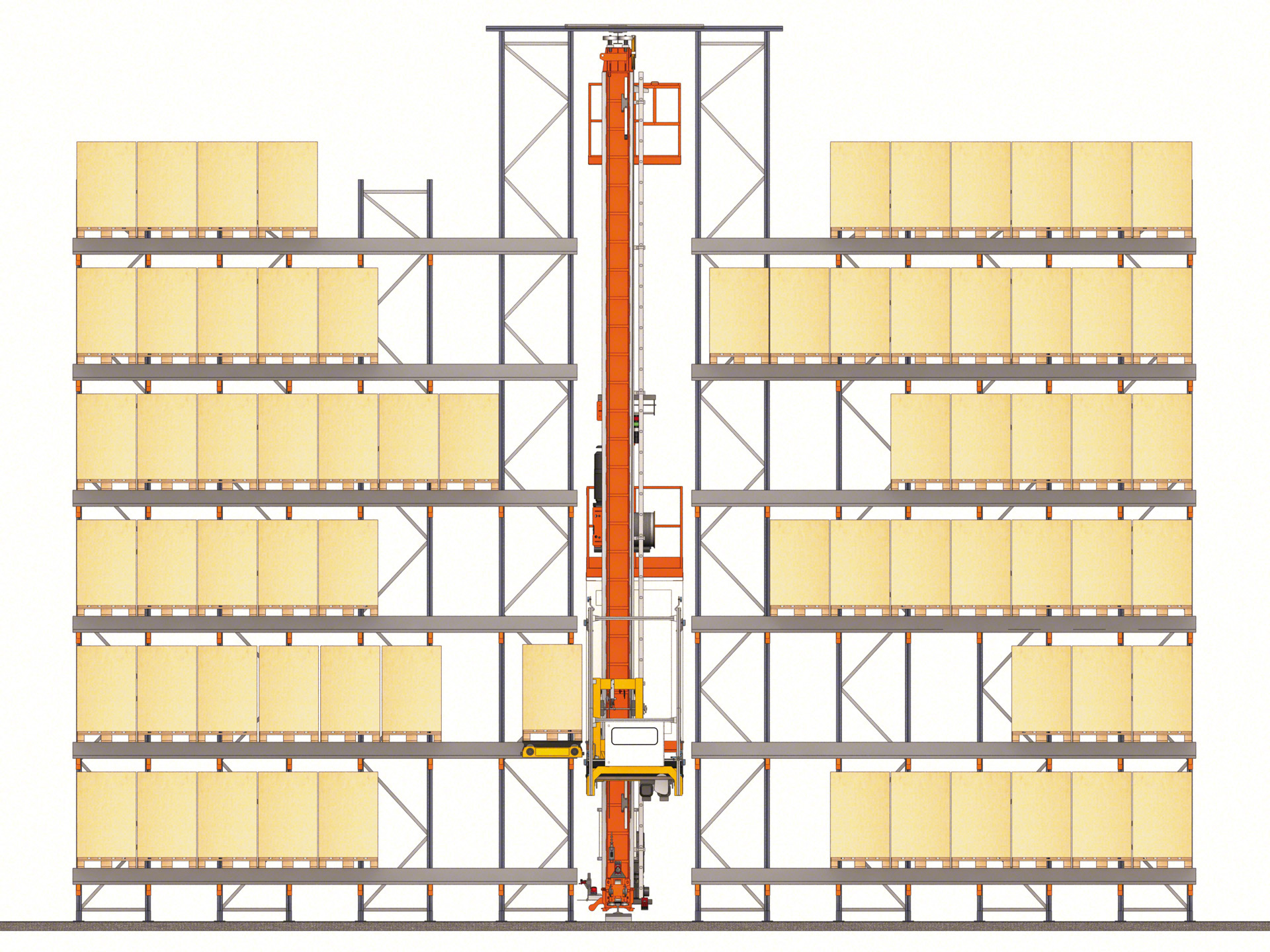

This system is base on the storage by accumulation principle, which enables the highest use of available space in terms of both area and height.

Drive-in racking is designed for the storage of homogenous products. It accommodates a large number of pallets for each SKU.

Advantages

- Maximum profitability of the available space (up to 85%).

- Removal of aisles between the ranking.

- Rigorous control of entries and exits.

- It allows as many SKU as loading lanes.

Two management systems are available: the drive-in system, with only one access aisle, and the drive-through system, with access to the load from both sides of the rack.

The system is frequently used in cold stores (refrigeration and freezing) which require maximum use of space for the storage of products in a controlled temperature.

Ask an expert