BY LUCA URCIUOLI

Adjunct Professor of Supply Chain Management at the MIT-Zaragoza Program

Over the last decades, supply chains have become globalised. Back in 1980, companies realised that outsourcing was a fundamental managerial practice for cutting costs and enhancing focus on their core competencies. Since then, usage of overseas suppliers has grown substantially, and nowadays, businesses manage to outsource 60-80% of their products from multiple suppliers.

The trend of outsourcing as a consequence of globalisation has brought major benefits to companies and societies. Businesses can implement structural changes that allow for cutting costs, reducing assets and focusing on R&D for their core products, services and components. When component manufacturing is shifted to externally contracted companies, the suppliers invited to join the supply chain are able to grow and gain technical specialisation, which would not have been possible working with solely one buyer. These suppliers can interact with several buyers, increasing economies of scale and reducing production costs. Overall, it can be said that outsourcing may improve product quality and, ultimately, reduce retail prices, resulting in a clear positive impact on societal welfare.

Despite the evident benefits of outsourcing and globalisation, past evidence shows that these practices may increase the vulnerability of supply chains to unexpected risks or disruptions. The logic is obvious: moving production to foreign countries decreases operational visibility and transparency. Companies may know very little about the local culture or political conditions of the countries from which they outsource. For instance, in some countries, political instability, war and/or riots could jeopardise operations unexpectedly and cause significant delays. The presence of corruption is also indicated as a known issue to be dealt with in some countries, which, ultimately, pushes up transaction costs.

Outsourcing and globalisation may increase the vulnerability of supply chains to unexpected risks or disruptions

Currently, the Covid-19 pandemic has laid bare these vulnerabilities, leading to a multitude of challenges in managing supply chains. The pandemic has affected the access to workforce and to the supply of components, raw materials, services, utilities, monetary funds and materials that all supply chains need to operate properly. Automotive manufacturers like Honda, Jaguar and Volkswagen experienced major financial difficulties during the Covid-19 crisis. Moreover, several suppliers decided to retract their trade credit offers, fearing the risk of default of their buyers. The shutdown of factories in supplying countries caused production delays in addition to congestion in both importing and exporting seaports, leading to queues and shipment delays. Retailers were literally assaulted by panicked consumers that emptied shelves, causing stockouts and increasing the risks of bullwhip effects. Finally, the introduction of governmental restrictions and remote working has ramped up demand for media entertainment products, causing a shortage in microchips and affecting the order lead times of supply chains in multiple industrial sectors, from telecommunications to the automotive industry.

A few days or weeks of production halts can actually result in significant and persistent long-term losses for companies, especially if the supply chain is intrinsically configured to outperform in terms of efficiency rather than to withstand disruptions. In this respect, lean management strategies aiming to minimise waste tend to reduce batch sizes, decrease inventory on hand, increase shipment frequency and, ultimately, expect deliveries to be just in time. However, when suppliers’ production is halted or when transport is delayed, there will be no buffers in retail shops or warehouses to fulfil customer demand. This is the case of the automotive sector, where a great majority of vehicles are built-to-order, many suppliers to factories in the US and the EU are located in Asia, and the sector is well known to widely implement lean production techniques. Hence, the Japan earthquake in 2011 produced consistent losses, estimated by experts as a downturn in automobile sales of about 640,000 units (Wheatley and Ramsay, 2011).

The length of the supply chain increases exposure to risks

Other managerial practices that may increase supply chain vulnerability relate to the usage of single or multiple sourcing. Single sourcing can bring considerable benefits in terms of building and managing relationships with suppliers; however, it can have devastating effects in the case of failures. Many recall the fire in Albuquerque, New Mexico, that interrupted supplies of microchips and led mobile phone manufacturer Ericsson to bankruptcy. Conversely, Nokia, which was using the same supplier, managed to survive this event, since its supply chain was configured to respond optimally to these accidents. Specifically, changes in product design and the establishment of additional supply sources were indicated as fundamental for replacing the unfortunate supplier and maintaining the production of mobile phones.

Likewise, the length of the supply chain increases exposure to risks. Sector professionals have a rule of thumb: freight at rest is freight at risk. In essence, the longer the transport distance to be travelled, the higher the number of risks encountered at the various links, and the longer the order lead time in the event that cargo is lost and needs to be back-ordered. For instance, many companies have experienced and are still experiencing the effects of the Suez Canal accident, when, in March 2021, the Ever Given vessel transporting over 18,000 TEU (twenty-foot equivalent unit) containers was pushed by strong winds, with its bow and stern becoming stuck in the canal banks, blocking the passage completely.

The impacts on supply chains trading between Europe, Asia and the Middle East were significant. Several shippers were affected by the accidental closure of the canal, not only those waiting for the containers moved by the Ever Given, but also those that had containers loaded on any of the 300 vessels waiting on either side of the canal. This totalled 16.8 million tonnes of dead weight, corresponding to a value of approximately $50 billion. Experts estimated the value of goods delayed at about $400 million per hour and about $9 billion per day. Losses were also registered by the Suez Canal authority, amounting to about $14-$15 million per day in transit fees. Once again, industries implementing lean techniques suffered the most, experiencing stockouts, bullwhip effects, lack of vessel capacity and higher freight rates. In addition, despite the fact that the canal has been reopened, the knock-on effects, implying increased congestion at seaports, are still being seen six months later.

In the face of risk and uncertainty, supply chains should be configured to trade off performance with the costs of risk prevention and mitigation measures

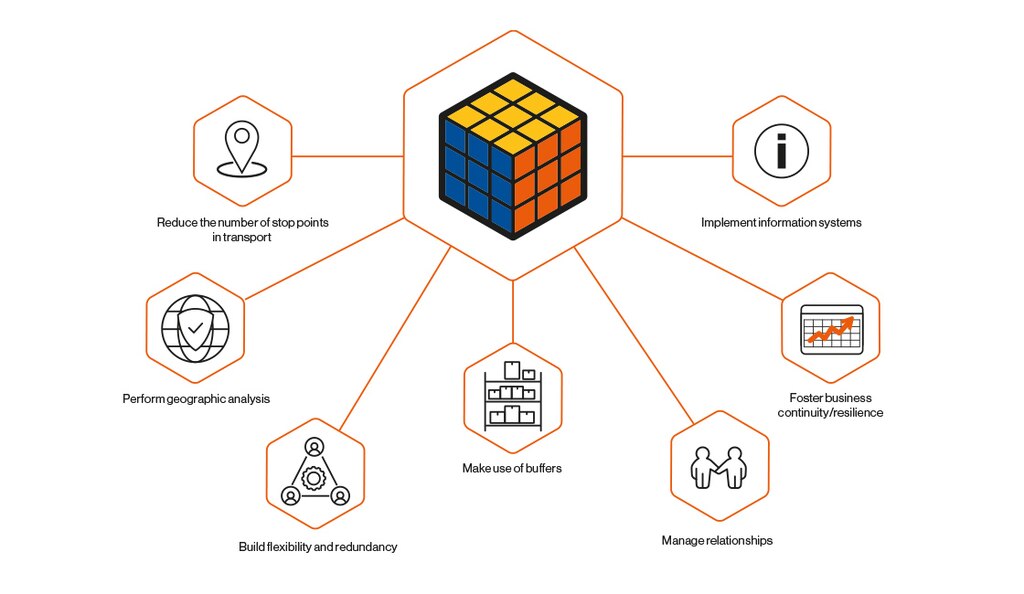

In the face of risk and uncertainty, supply chains should be configured to trade off performance with the costs of risk prevention and mitigation measures. The following are several potential practices suggested by research:

- Reduce the number of stop points in transport. Freight at rest is freight at risk, especially at risk of theft or hijacking. Security risks increase when cargo stops in a seaport, a terminal, a gas station to refuel or on the roadside when the driver rests. A transport planner may preventively arrange the shipping route by minimising these stop points.

- Perform geographic analysis. On a more strategic level, companies may decide to avoid selecting suppliers from geographic regions exposed to natural hazards or where security risks are known to be present and difficult to eradicate. Relocating factories or logistics operations is a complex task; therefore, a thorough evaluation of the impacts on the overall business needs to be considered and traded off with the benefits of reducing or eliminating certain risks.

- Build flexibility and redundancy. Some activities, such as manufacturing, could be duplicated, for instance, shifting the outsourcing of the same product or component from single to multiple suppliers. Preferably, suppliers should be well diversified in terms of risks, e.g., located in different geographic areas. Increasing the number of contracted suppliers for the same component will inevitably affect costs; on the other hand, the supply chain will ultimately be more responsive to accidents. Flexibility can also be integrated in transport, designing alternative routes, or in production, enabling factories to rearrange their production lines to duplicate manufacturing, whenever possible.

- Make use of buffers. Buffering strategies are also well-known solutions, as they can be used to build slack into the supply chain and ensure its productivity in case of a disruption and a halt in supply flows. Buffers can expand capacity to hold more inventory than needed or serve as time buffers in intermodal terminals to ensure optimal modal shift.

- Manage relationships. The type of relationship established with a supplier will determine the degree of transparency of its operations and financial health. Trust in sharing information is typically mentioned as a determining factor. A supplier that is under pressure to outperform its competitors may decide not to share information about its threats and vulnerabilities. Lack of visibility of potential threats leads to unexpected manifestations of risks, increasing monetary losses to mitigate impacts.

- Foster business continuity/resilience. Despite prevention strategies and tools in place, a risk event can still impact a company. Hence, it is of the utmost importance that processes are planned and put into place to ensure that businesses can quickly respond and prevent escalation.

- Implement information systems. IT solutions exist today to monitor in real time suppliers and flows of cargo during transport. In addition, these systems can be connected to third-party services in order to gather information in real time about weather forecasts and events such as natural hazards, traffic conditions, congestion in terminals, etc. These tools are proving to make exceptional differences in decision-making in the presence of uncertainty.

Practices for managing risk in supply chains

Companies with robust risk management strategies in place can gain a competitive advantage and thereby solidify their leadership position in the market

Benefits of risk management

Managing risks in supply chains has proven to be beneficial for businesses. Additional costs such as those arising when shipments are delayed or lost, products are damaged, suppliers’ production is halted or quality is not acceptable can be reduced significantly.

Apart from the well-known cost-reduction effects, research shows that companies with robust risk management strategies in place can gain a competitive advantage and thereby solidify their leadership position in the market. Nokia’s prompt reaction when the microchip supplier in New Mexico had to halt production is a clear example demonstrating that organisations capable of managing their risks can transform challenges into opportunities, i.e., gaining market shares if their competitors go bankrupt.

Another potential benefit for establishing an excellent risk management plan is the possibility to engage in riskier business. There’s a well-known saying that goes “those who don’t take risks don’t drink champagne.” Hence, while a risk-taking attitude may bring companies greater rewards, risk management plans can help to control risks and mitigate their consequences.

Dr. Luca Urciuoli is an Adjunct Professor of Supply Chain Management at the MIT-Zaragoza International Logistics Program. He is also an Associate Professor at the KTH Royal Institute of Technology (Stockholm, Sweden) and a Research Affiliate at the MIT Center for Transportation & Logistics (MIT CTL).

References

- Chopra, S., Sodhi, M., & Lücker, F. (2021). Achieving supply chain efficiency and resilience by using multi-level commons. Decision Sciences.

- Elahi, E. (2013). Risk management: the next source of competitive advantage Foresight.

- Ivanov, D., Tsipoulanidis, A., & Schönberger, J. (2017). Global supply chain and operations management. A decision-oriented introduction to the creation of value. Springer texts in Business and Economics.

- McKinsey (2021). The future of work after COVID-19, https://www.mckinsey.com/featured-insights/future-of-work/the-future-of-work-after-covid-19.

- Russon, M.A. The cost of the Suez Canal blockage. BBC News. Available at: https://www.bbc.com/news/business-56559073.

- Sheffi, Y. & Rice JR, J. B. (2005). A supply chain view of the resilient enterprise. MIT Sloan Management Review, 47, 41.

- Urciuoli, L., (2017). Automating supply chain resilience should be high on your digital agenda. MIT Sloan Management Review. Available at: https://sloanreview.mit.edu/article/automating-supply-chain-resilience-should-be-high-on-your-digital-agenda/.

- Wagner, S. M. (Ed.). (2009). Managing risk and security: The safeguard of long-term success for logistics service providers (Vol. 16).Haupt Verlag AG.

- Wheatley, M. and Ramsay, M. (2011). After the disaster in Japan. Available at: https://www.automotivelogistics.media/after-the-disaster-in-japan/7408.article.